Our daily use of face masks is gradually evolving into the new major source of white pollution after garbage bags.

A 2020 study estimated that 129 billion face masks are consumed every month, most of which are disposable masks made from plastic microfibers. With the COVID-19 pandemic, disposable masks have been promoted in most countries to prevent COVID-19 infection because they can help prevent the spread of COVID-19 and other diseases, making this data constantly updated.

However, in such a scenario of high usage, no country has made “official” recycling guidelines for masks, which leads to more waste disposal of these discarded masks as solid waste, which poses a greater challenge to global plastic pollution control.

Finding a sustainable solution to the global plastic pollution problem caused by disposable masks is imperative.

Recently, two biotechnology researchers from Gazamada University proposed that pandemic-related mask waste could be disposed of with biodegradable disposable masks made from pineapple leaves.

The biodegradable disposable masks are mainly made of fibers from pineapple leaves, and because they use natural fibers instead of plastic fibers, microorganisms such as fungi or bacteria can begin the degradation process more quickly after immersion in the soil (expected to take three days).

Figure | Pineapple leaf fiber production process: pineapple cultivation (A), pineapple fruit (B), fiber extracted from pineapple leaves (C), pineapple leaf fiber produced in Indonesia (D) (Source: Hindawi).

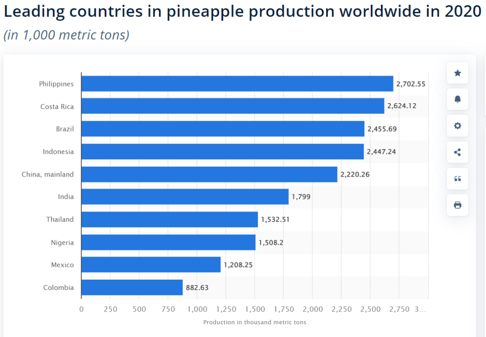

It is understood that pineapple is very common in tropical areas, the relevant information shows that the global pineapple production reached 27.82 million tons in 2020. Pineapple leaves have one of the highest known natural fibers in fiber content (close to 80%), and there are many ways to extract fiber from pineapple leaves, making pineapple leaf fiber considered a good alternative to plastic fiber by biotechnology researchers.

Figure | World Leading countries in pineapple production in 2020, among which the Philippines, Costa Rica and Brazil are the world’s three largest pineapple producers (source: Statista).

Pineapple leaf fibers are white, have a filamentous sheen, have high tensile strength, have a finer texture than other plant fibers (such as hemp, jute, flax, and canna), and are easy to stain. Pineapple leaf fibers are arranged in the same way as cotton, but they are more environmentally friendly than cotton.

Cotton is traditionally grown with pesticides and fertilizers, and is manufactured with harsh chemicals, some of which remain and cannot be washed off. Pineapple leaves, on the other hand, are grown without any supplements and can be regenerated annually and easily obtained.

Currently, a large amount of pineapple leaves are produced each year, except for a small portion that is made into pineapple leaf fiber and used in raw materials and energy production (such as making rope, twine, composite materials and clothing products). Usually discarded as agricultural waste, the rational use of these pineapple leaves will not only reduce environmental pollution, but also bring some economic benefits.

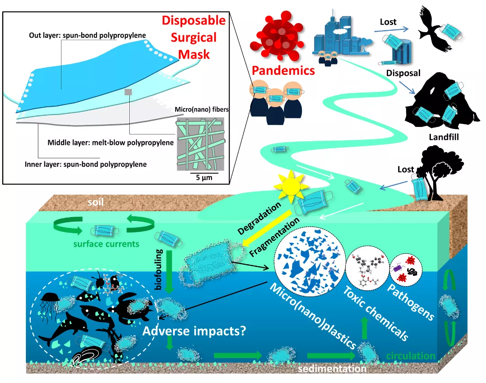

How important are biodegradable disposable masks for humans? A common disposable surgical mask consists of three layers of polymer. The outermost layer is a non-absorbent material (such as polyester), the middle layer is a non-woven fabric (such as polypropylene and polystyrene) made using a melt-blown process, and the inner layer is an absorbent material such as cotton. Polypropylene, the most common material used in mask production, is so difficult to break down that it can remain in the ecological environment for decades, and possibly hundreds of years, to turn into microplastics and nanoplastics.

In addition to causing plastic contamination, discarded masks may even accumulate and release harmful chemicals and biological substances, such as Bisphenol A (BPA), heavy metals, and pathogenic microorganisms. Among them, bisphenol A has been pointed out to have carcinogenic effect.

In addition, other studies have shown that masks can even be transported from land to freshwater and Marine environments via surface runoff, river discharge, ocean currents, wind, and animals (via entanglement or ingestion) if not properly collected and managed. According to a 2020 report by OceansAsia, “An estimated 1.56 billion face masks will enter the ocean in 2020, resulting in an additional 4,680 to 6,240 tons of Marine plastic pollution.”

Figure | Potential environmental fate and Impact of disposable surgical masks (Source: FESE)

It can be said that with the normal development of the epidemic, the waste of masks will only accumulate more and more, and the pollution to the ecological environment will only become greater and greater. Disposable masks made from pineapple leaf fibers, which degrade naturally and do not release harmful toxins, could be a solution to plastic pollution caused by masks.

However, due to the hydrophilic nature of pineapple leaf fiber, it is not as strong and durable as plastic. More research is needed to address this challenge.

Post time: Aug-15-2022