From yarn to cloth

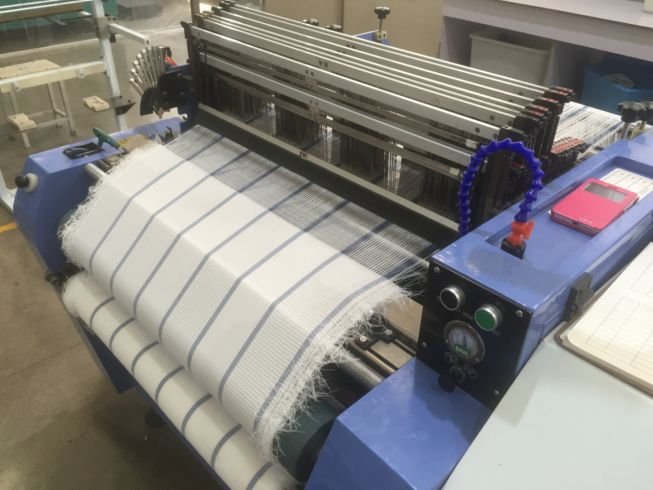

Warping process

Convert the original yarn (package yarn) into warp yarn through the frame.

Sizing process

The cilia of the original yarn are compressed by the slurry, so that the cilia are not pressed on the loom due to friction.

Reeding process

The warp yarn is put on the reed of a loom and used for weaving the required width and warp density.

Weaving

Jet

Finished product embryo inspection

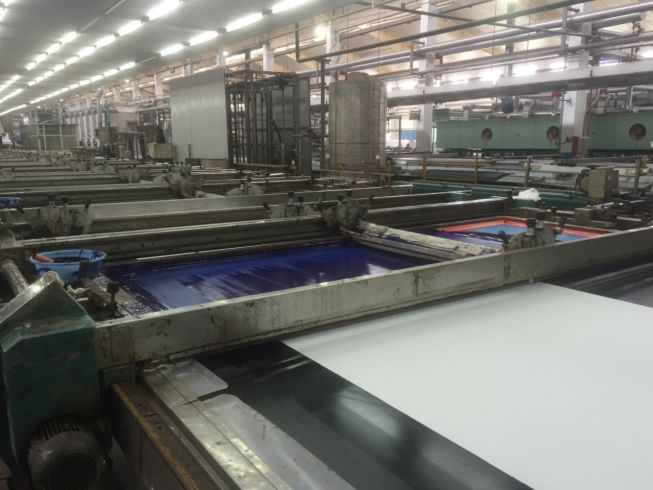

Dyeing Process

Bad cloth pretreatment

Singeing: remove the fluff from the cloth surface to make the cloth surface bright and clean and beautiful, so as to prevent uneven dyeing or printing defects due to the existence of fluff during dyeing or printing.

Desizing: remove the size of grey cloth and the added lubricant, softener, thickener, preservative, etc., which is conducive to the subsequent scouring and bleaching process.

Scouring: remove the natural impurities of grey cloth, such as wax, pectin, nitrogen-containing substances and some oil agents, so that the fabric has certain water absorption, which is convenient for the adsorption and diffusion of dyes in the printing and dyeing process.

Bleaching: remove the natural pigment, cottonseed shell and other natural impurities on the fiber, endow the fabric with necessary whiteness, and improve the brightness and dyeing effect of dyeing.

Mercerization: through concentrated caustic soda treatment, it can obtain stable size, durable luster, improve the adsorption capacity of dyes, and improve the physical and mechanical properties such as strength, elongation and elasticity.

Types of common dyes

Direct dye: direct dye refers to a kind of dye that can directly dye cotton fiber by heating and boiling in neutral or weak alkaline medium. It has high directness to cellulose fibers and does not need to use dyes that can color fibers and other materials by relevant chemical methods.

Reactive dye: it is a water-soluble dye. Its molecules contain active groups, which can covalently bond with hydroxyl groups on cellulose molecules under weak alkaline conditions. Reactive dyes generally have good fastness to sunlight. After full washing and floating, they have high soaping fastness and rubbing fastness.

Acid dye: it is a kind of water-soluble dye with acid group in the structure. It is dyed in acid medium. Most acid dyes contain sodium sulfonate, which can be dissolved in water, with bright color and complete chromatography. It is mainly used for dyeing wool, silk and nylon. It has no coloring power for cellulose fibers.

Vat dyes: vat dyes are insoluble in water. When dyeing, they must be reduced and dissolved into leuco sodium salt in alkaline strong reducing solution before dyeing the fiber. After oxidation, they return to insoluble dye lakes and are fixed on the fiber. Generally, they have high washing and sun fastness.

Disperse dyestuff: disperse dyestuff has small molecules and no water-soluble groups in its structure. It is uniformly dispersed in the dye solution with the help of dispersant. The polyester cotton dyed with disperse dyes can be dyed with polyester fiber, acetate fiber and polyester amine fiber, becoming a special dye for polyester.

Flat screen printing

Rotary screen printing (flat / diagonal)

Finishing

Stretching, weft setting, sizing, shrinking, whitening, calendering, texturing, roughening, shearing, coating, etc

Stretching

Mercerizing

weft setting

Rapier

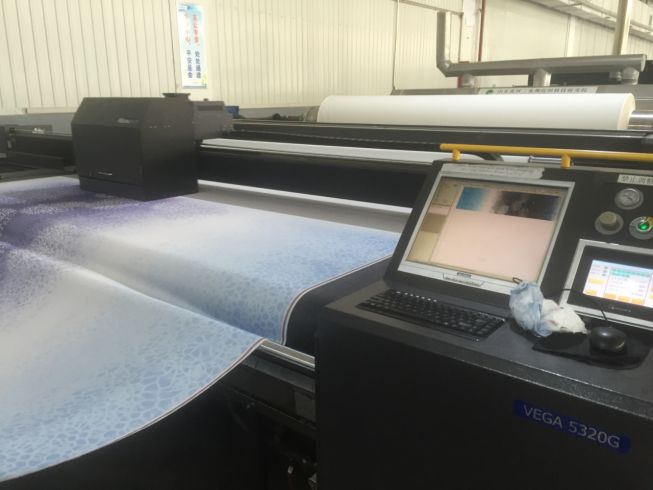

Digital printing

Soft air

Content extracted from: fabric course

Post time: Jun-28-2022