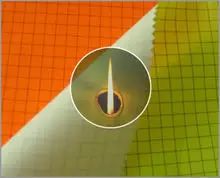

Foreword:Textile coating finishing agent, also known as coating glue, is a kind of polymer compound evenly coated on the surface of fabric. It forms one or more layers of film on the surface of the fabric through adhesion, which can not only improve the appearance and style of the fabric, but also increase the function of the fabric, so that the fabric has special functions such as water resistance, water pressure resistance, ventilation and moisture permeability, flame retardance and pollution prevention, light shielding and reflection.

Development history

More than 2000 years ago

In ancient China, the coating glue was already used on the surface of fabrics. At that time, it was mostly natural compounds such as lacquer and tung oil, which were mainly used for the production of waterproof cloth.

modern

A variety of synthetic polymer coating adhesives with excellent performance have emerged. The original product had the defect of only being waterproof but not permeable to moisture. The coated fabric felt stuffy and hot when used, and its comfort was poor.

Since 1970s

Researchers have developed a series of waterproof and moisture permeable coating adhesives for fabrics by modifying the chemical structure of coating adhesives and changing the coating processing methods.

In recent years

Functional coating adhesives and composite coating adhesives have also made great progress

Classification by chemical structure

1. Polyacrylate (PA):

Also known as AC adhesive coating, it is the most common and common coating at present. After coating, it can increase the hand feel, windproof and sag.

PA white glue coating, that is, coating a layer of white acrylic resin on the surface of the fabric, can increase the coverage of the cloth, make it opaque, and make the color of the cloth more bright.

PA silver glue coating, that is, a layer of silver white glue is coated on the surface of the fabric, so that the fabric has the function of shielding light and radiation. It is generally used for curtains, tents and clothing.

2. Polyurethane (PU):

After coating, the fabric feels plump and elastic, and the surface has a film feeling.

Pu white glue coating, that is, a layer of white polyurethane resin is coated on the surface of the fabric, and its function is basically the same as that of PA white glue, but the Pu white glue coating has a fuller feel, more elasticity and better fastness.

Pu silver glue coating has the same basic function as PA silver glue coating. However, Pu silver coated fabric has better elasticity and better fastness. For tents and other fabrics requiring high water pressure, Pu silver coated fabric is better than PA silver coated fabric.

3.Polyvinyl chloride (PVC):

It is made of glass fiber cloth, glass cotton cloth and chemical fiber cloth and coated with special process. Its main performance features are: waterproof, flame retardant, mildew proof, cold proof and corrosion proof (referred to as "three proof cloth" and "five proof cloth"); Aging resistance; UV protection; Easy to clean; High temperature resistance (180 ℃) and good thermal insulation.

4. Silicone:

Silicone high elasticity coating, also known as paper coating. Thin cotton is very suitable for making shirt fabric. It feels full, brittle and elastic, with strong resilience and wrinkle resistance. For thick fabrics, it has good elasticity and fastness.

5. Synthetic rubber (such as neoprene).

In addition, there are polytetrafluoroethylene, polyamide, polyester, polyethylene, polypropylene and proteins.

At present, polyacrylates and polyurethanes are mainly used.

Post time: Sep-16-2022