With the development of knitting industry, modern knitted fabrics are more colorful. Knitted fabrics not only have unique advantages in home, leisure and sports clothing, but also are gradually entering the development stage of multi-function and high-end. According to the different processing methods of knitted clothing, it can be divided into knitted molding clothing and knitted cutting clothing.

Knitted garment

Knitted shaped clothing uses the unique forming method of knitting. After selecting the yarn, the yarn is directly woven into pieces or clothes. It mainly depends on the computer flat knitting machine to set the program and knit the pieces. It is usually called “sweater”.

Knitted shaped clothing can be quickly renovated and changed in style, color and raw materials, and follow the trend, which can maximize the aesthetic pursuit of designers and consumers who are constantly updating. In terms of production methods, it can also directly design styles, patterns and specifications on the computer, and directly design the knitting process by the program, and then import such a program into the control area of the knitting machine to automatically control the machine for knitting. Due to the above advantages, modern knitwear has gradually entered the stage of multi-function and high-end development, which is welcomed by consumers.

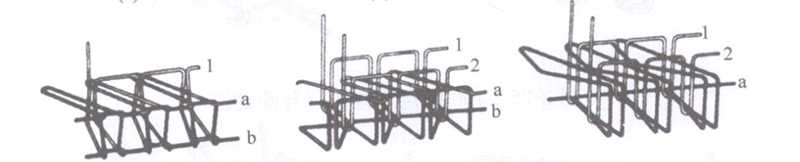

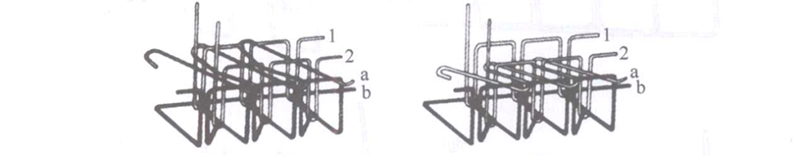

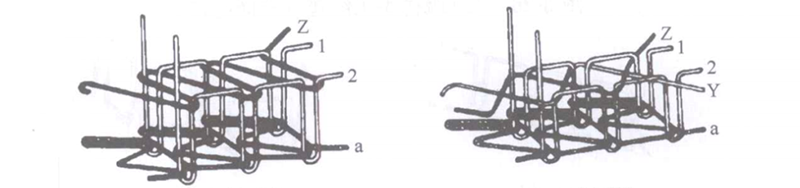

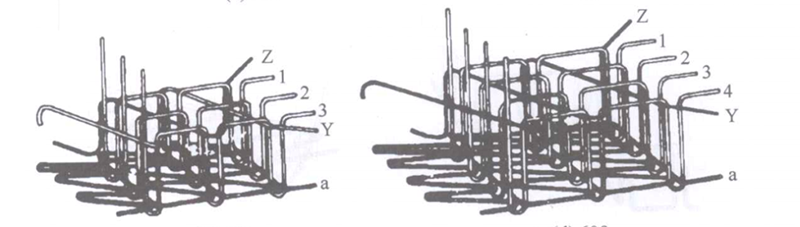

Computerized flat knitting machine

The design of knitted garment woven by computerized flat knitting machine can start from the source of garment design – yarn. Through the changes of yarn color, texture, thickness, fabric structure and density, as well as the changes of finishing methods, the space presented by the design is richer and broader.

Circular knitting machine

Hosiery machine, glove machine and seamless underwear machine transformed from hosiery machine are collectively referred to as knitting molding machine. With the rapid popularity of sports trends, the design and presentation of sportswear continue to innovate. Seamless technology is more and more used in the production of high elastic knitted underwear and high elastic sportswear, so that the neck, waist, buttocks and other parts do not need to be seamed at one time. The products are comfortable, considerate, fashionable and changeable, and have both a sense of design and fashion while improving comfort.

Knitted cut clothing

Knitted cut-out clothing is a kind of clothing made of various knitted fabrics through design, cutting, sewing and finishing, including underwear, T-Shirts, sweaters, swimwear, home clothes, sportswear, etc. Its production process is similar to that of woven clothing, but due to the different structure and performance of the fabric, its appearance, wearability and the specific methods of production and processing are different.

Chain sewing machine

Overlock sewing machine

Stretch sewing machine

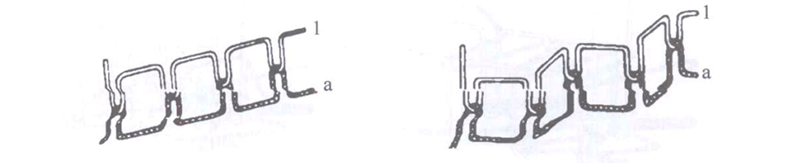

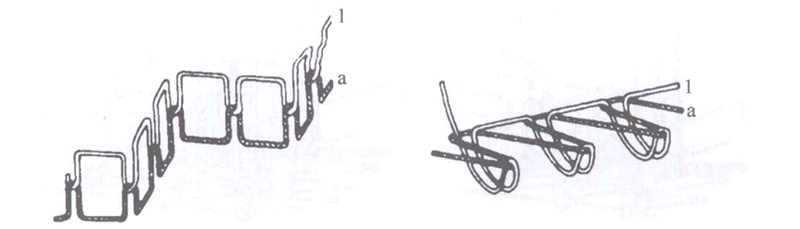

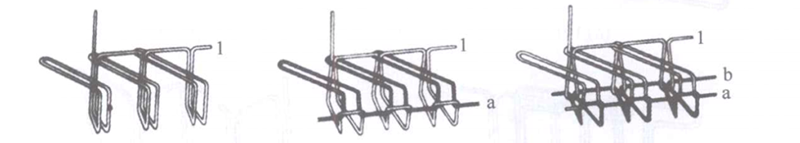

The tensile and detaching properties of knitted fabrics require that the stitches used to sew the cutting pieces must be compatible with the extensibility and strength of knitted fabrics, so that the sewn products have a certain degree of elasticity and fastness, and prevent the coil from detaching. There are many kinds of stitches commonly used in knitted clothing, but according to the basic structure, they are divided into chain stitches, lock stitches, bag stitches and tension stitches.

—-Article excerpted from FDC fabric Library

Post time: Jul-19-2022